My ideal yogurt is Greek yogurt, which is thick, rich, flavourful, and made of sheep's milk. Unable to find whole sheep's milk, I'm experimenting with goat's milk from Fairwinds Farm of Fort Macleod, Alberta, as it is fattier (and just more Greek) than cow's milk.

My ideal yogurt is Greek yogurt, which is thick, rich, flavourful, and made of sheep's milk. Unable to find whole sheep's milk, I'm experimenting with goat's milk from Fairwinds Farm of Fort Macleod, Alberta, as it is fattier (and just more Greek) than cow's milk.There are two ways to make yogurt at home. The first is to add a small amount of commercial yogurt containing active cultures to milk. The second is to use pure bacterial cultures. Regardless of which method you use, the process is basically the same.

Danlac Starter Kit

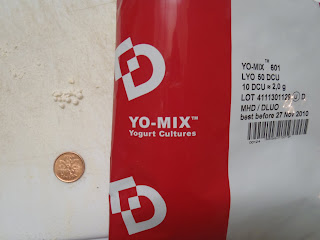

I eventually want to make cheese with pure bacterial cultures. I contacted Danlac in Airdrie, and ordered a starter kit containing several doses of rennet and cultures for yogurt, mozzarella, and feta.

The rennet and cultures were put in an envelope and mailed to me. The recipes for yogurt, feta, and mozzarella were e-mailed. Danlac's motto is "Serving the food industry," not "Serving the interested individual," and the recipes reflect that fact: they're more like industrial specifications than recipes. There are values measured in pounds per square inch, and mention of back pressure valves and plant conditions. All the relevant temperatures and times are listed, but to understand exactly how the process might be done in a kitchen, I consulted a few of the several hundred sources on the internet.

Yogurt: A First Attempt

Mise en Place

First, in my kitchen sinks, I set up an ice bath and a 45°C warm water bath. The first is for cooling the hot milk, the second is for holding the milk at the bacteria's incubation temperature.

Next I measured out the yogurt cultures. The YO-MIX 601 packet I received contains freeze-dried pellets of the two most common cultures used in yogurt production: Lactobacillus bulgaricus, and Streptococcus thermophilus. The problem is that the packet is designed to inoculate 500L of milk, and only weighs 7g. I wanted to inoculate 4L of milk, which means that I would need 0.0056g of yogurt cultures. Unfortunately, my weigh-scale is not that precise.

4L divided by 500L is 0.008.

I poured the bacteria onto a cutting board. Using a butter knife, I roughly divided the contents into five piles, then split one of the those piles into ten. I continued eye-balling smaller and smaller divisions until I had approximately eight thousandths of the original pile balanced on the end of my knife. It was about a pinch. Go figure. This is sure to be a huge source of inconsistencies between batches. I slid the rest of the pellets into a small ziploc and put them in the freezer, as per storage instructions on the packet.

Heat the Milk

The first step in making yogurt is heating the milk and holding it at 85°C for five minutes. Besides killing any micro-organisms in the milk (which is completely redundant if you're using pasteurized dairy), the heat induces a mysterious change in the milk proteins that helps them set properly once coagulated. I heated my milk plain and simple on my stove top.

Cool the Milk to Incubation Temperature

Next the milk is cooled to around 42°C, which is the ideal temperature for the bacterial cultures. I transferred my pot to the ice bath. After a couple minutes of stirring, it had dropped to 45°C.

Pitch Cultures and Incubate

With my milk temperature hovering around 42°C, I pitched my yogurt cultures. The milk now had to be held very close to this temperature for the next several hours.

There are lots of ideas on the internet for holding your milk at this awkward temperature, which too warm for room temperature, and too cool for an oven. I tried a simple system of thermal isolation. I tightly covered my stainless steel pot of milk, put it in the warm water bath at 45°, and covered the whole bath with plastic, and then with a thick towel. It made for a surprisingly closed system. My water bath lost a little more than 2°C every hour, at which time I would replace a few cups of water from the bath with hot water. Setting up the warm water bath in a large plastic cooler would probably work even better.

Length of Incubation

In industry, fermentation is stopped when the pH of the milk is around 4.50. I don't have any titration tools, but my Danlac recipe provided the following rough time-line: if your milk is held at 42°C, it should take six hours to reach 4.50pH, and if your milk is held at 38°C, it should take eight and a half. Though you don't want lose heat or disturb the fermentation by opening the pot too often, thickness and taste are the best indicators of when to stop the process. I ended up letting mine incubate for a little over twelve hours. This was maybe because of the inaccuracy of my yogurt culture measurement, but also because my incubation temperature slipped into the cooler end of the acceptable spectrum for a few hours.

Stir

Next was by far the most ambiguous step in the recipe: "Treatment of coagulum according to desired consistency by: stirring, using back pressure valve for improving structure, homogenizing." I ignored the second and third options, as they didn't sound like tasks I could perform in my kitchen. I stirred my yogurt, mixing the loose curd structures and whey together.

Let the Yogurt Set

Finally I left the yogurt in the fridge for twenty four hours to cool and "form a solid network".

Results

The end product was acceptable, though a little thin. After straining with cheesecloth it was much closer to my thick, creamy Greek-style yogurt. It has a very pleasing, mild acidity that is rarely found in commercial products, which tend to be a little harsh.

I think next time I'm going to use 1/8 tsp of the yogurt cultures, about double what I added this time. Hopefully that will make the process run a bit quicker, and result in a thicker product.

I make excellent yogurt and yogurt cheese. I have been doing so for years - and have posted it and video taped it on my site. The marinated cheese ball recipe is deadly. I have never used a starter. Always a live culture. Great post.

ReplyDelete:)

Valerie

Greaat post thanks

ReplyDelete